Description

CAPACITY: 0 – 1000 TONS

MORELLO designs and manufactures automated guided carts AGV focusing on particular demands and requests from our customers in a variety of industrial sectors. Our expertise is heavy-load AGV cart with high capacity from 2 up to 1,000 tons.

We manufacture automated guided vehicles (AGV) on wheels for automation of material handling in a variety of industries. AGV can operate in complete autonomy without operator or any physical guidance like rails

ADVANTAGES OF MORELLO HEAVY-LOAD AGVs

- Reduction of operational costs

- Advanced security

- Increased accuracy and productivity

- Reduction of damage to products and work environment

- Possibility of working in dangerous or hostile environment (for example explosive environment)

NAVIGATION TECHNOLOGY

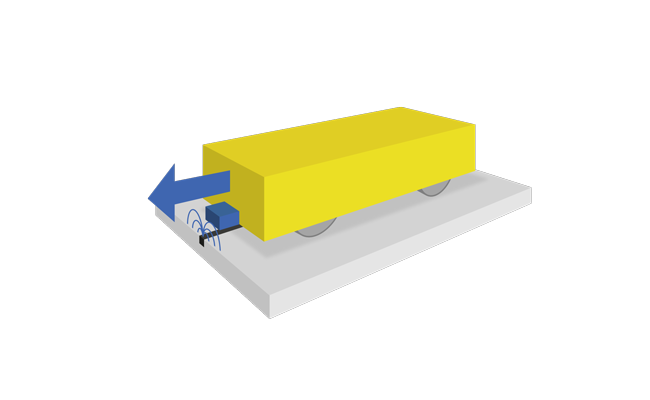

Variety of navigation technologies for automated material handling defines MORELLO among automated guided vehicle manufacturers worldwide. Selection of technology (or a mix of multiple technologies) is made together with customer, according to his particular requirements, technical features and budget. Here are the technologies that can be used with our heavy-load AGV cart.

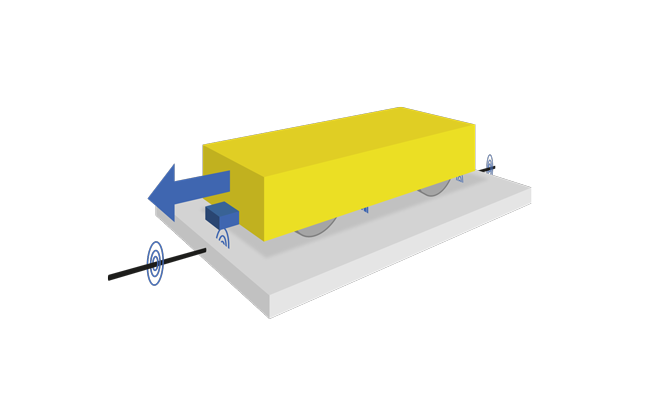

INDUCTIVE GUIDANCE

OPTICAL GUIDANCE

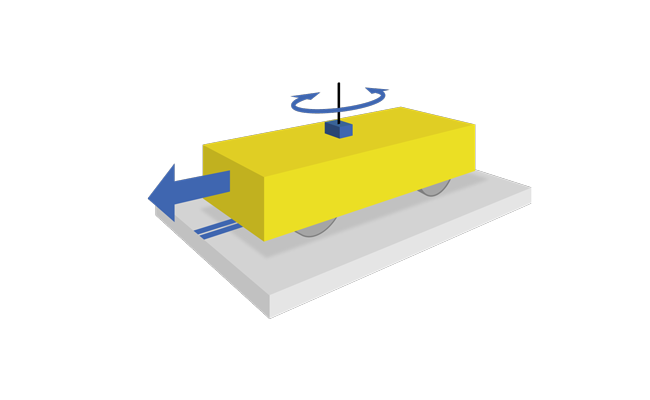

INERTIAL GUIDANCE

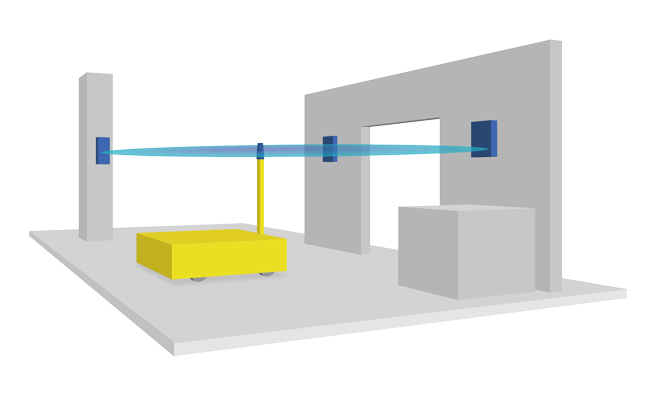

LASER GUIDANCE

MAGNETIC GUIDANCE

dGPS GUIDANCE

SOFTWARE

MORELLO uses a mix of proprietary software developed internally and standard software developed by AGV software-house leaders, to ensure maximum flexibility in in heavy-load AGV cart geometry customization, including paths to follow and automation logics that are part of the customer’s production process. We can offer omnidirectional automated guided carts as well as AGV carts with multiple simultaneous navigation technologies, solutions with interface with all types of management systems, AGV trolleys that interfacing with automated warehouses and other automatic machines, AGV Atex carts and much more.

AGV ATEX for hazardous environments

MORELLO is probably the first Company in the world that can offer to its customers AGVs suitable for hazardous areas. Thanks to our deep knowledge of ATEX environment we can design and manufacture customized AGV suitable for ATEX Zone 2 areas. The ATEX automated guided carts are a very big step ahead to increase the safety in all that environments that are not safe as per their nature. In fact, thanks to these explosion proof AGVs, it is possible to reduce the operators work inside hazardous environment, minimizing the possible accidents.

Technical characteristics

Capacity | from 1 ton to over 1000 tons | |

Dimensions | on request | |

Steering systems | front axle, all axles, ± 90° steering, omnidirectional | See the technology |

Power supply | battery (electric grid or diesel generator on request) | See the technology |

Travel speed | on request (from 1 km/h to 6 km/h) | |

Drive motors | AC motors (hydraulic motors on request) | See the technology |

Steering motors | AC motors (hydraulic motors on request) | See the technology |

Command | touch panel on board, notebook/s, pulpits, customer WMS/ERP | |

Navigation technologies | inductive, magnetic, laser, natural, dGPS, optical, inertial | |

Kind of wheels | solid rubber, polyurethane, pneumatic | |

Lifting deck | on request (lifting stroke from 50 mm) | |

Kind of battery | lead acid, gel, lithium, pure lead | |

Battery life | on request (from 1500 m to over 15000 m) | |

Climbing ability | on request (from 1% to over 20%) | |

Operating environment | indoor, outdoor, offshore | |

Safety devices | laser scanners, sensitive bumpers, ultrasonic sensors | See the technology |

Industry 4.0 ready | yes | See the technology |

Hazardous areas conform (EX) | on request (ATEX – only Zone 2) | See the technology |