Description

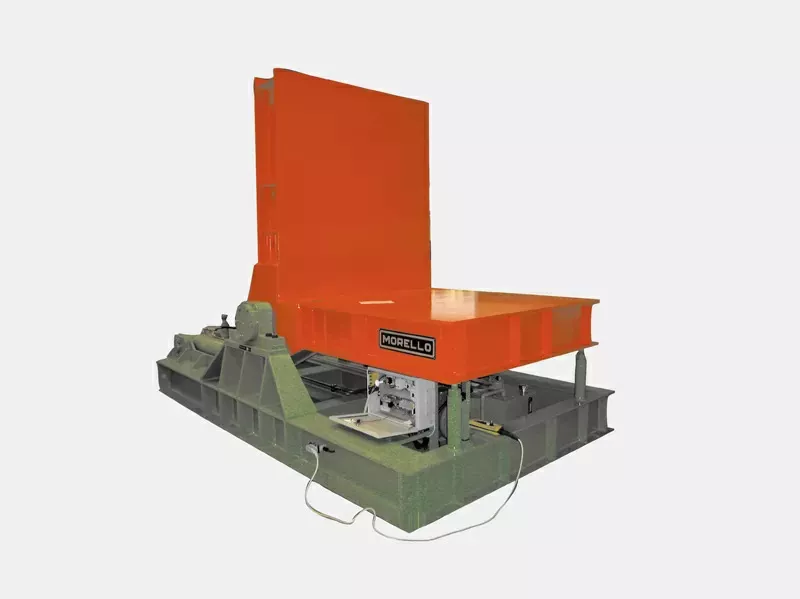

Upenders for coil, dies and other heavy materials

CAPACITY: 0 – 200 TONNES

Upender or Tilter is widely used all over the world providing modern demanding industries with enhanced productivity and extreme safety during 90°, 180° and 360° tilting of large and very heavy materials. Overhead cranes or forklifts to upend heavy loads are widely used nowadays by the companies requiring a high level of safety and productivity. With the current metalworking industry changing so rapidly, flat deck mold upender provides modern problem-solving solutions for industrial handling of mold, tooling and die

Dedicated machine for upending allows an operator to unload overhead cranes. Upender is completely safe since it avoids holding the load raised during tilting, in this way operators are safe from difficult and dangerous manoeuvres. Morello supplies flat deck upender for mold, dies, coils, castings and other material handling in a variety of manufacturing industries all over the world.

Morello’s upenders can be customized according to special needs: payload, loading deck size and covers, tilting speed and other options can be studied together with the client. Morello pays particular attention to design of heavy load solutions with high capacity from 10 tonnes to over 200 tonnes.

Technical characteristics

Capacity | from 1 ton to over 200 tons | |

Dimensions | on request | |

Tilting angle | 90° / 180° / 360° | |

Loading deck material | steel, wood, plywood, rollers | |

Tilting system | hydraulic cylinders, electric gear motors, chains | |

Command | pendant panel, remote controller, pulpit, customer WMS/ERP | |

Load locking and centering | on request | |

Operating environment | indoor, outdoor, offshore | |

Safety devices | laser scanners, sensitive bumpers, photoelectric sensors | See the technology |

Industry 4.0 ready | on request | See the technology |

Hazardous areas conform (EX) | on request (ATEX, IECEx, NEC 500) | See the technology |

Automation | on request |